Vacuum inspection

Applying artificial vision to quality control

Technical file

Type of innovation: Device

Scope: Bioengineering

Innovation leader: Shared leadership

Year: 2005

Period: From 2003

Geographical scope: International

Economic impact: Medium

Level of innovation: Evolutionary

Patent: Yes

Interdisciplinary connections: -

The origins of artificial vision

The origins of artificial vision can be traced back to the invention of photography. The first ever photograph was taken by French chemist Nicéphore Niépce in 1826, and the science of photography developed steadily throughout the 19th and 20th centuries. By the 1960s the first efforts to simulate human vision in computers were underway. However, the challenge of combining optical technology with artificial intelligence to mimic human vision proved far greater than had initially been imagined. The more neuroscientists learned about how the brain processes visual images, the more aware they became of just how difficult it would be to reproduce the human visual faculty.

Using artificial vision to study clotting reactions

Instead, attention focused on specific applications of artificial vision. In hematology, one such application was in the study of clotting reactions. Such tests were performed manually, with a technician or clinician observing the formation or dissolution of the blood clot.

Developing the new technology

In 1991, in partnership with the Polytechnic University of Barcelona, Grifols undertook a viability study into the development of a system to detect coagulation. Although this system never got beyond the initial stage, the project brought two developments. Firstly, the visual detection techniques on which the system was based were found to be viable. And secondly, Grifols had acquired a range of technology for the project that would lay the foundations for future efforts.

Artificial vision technology in manufacturing processes

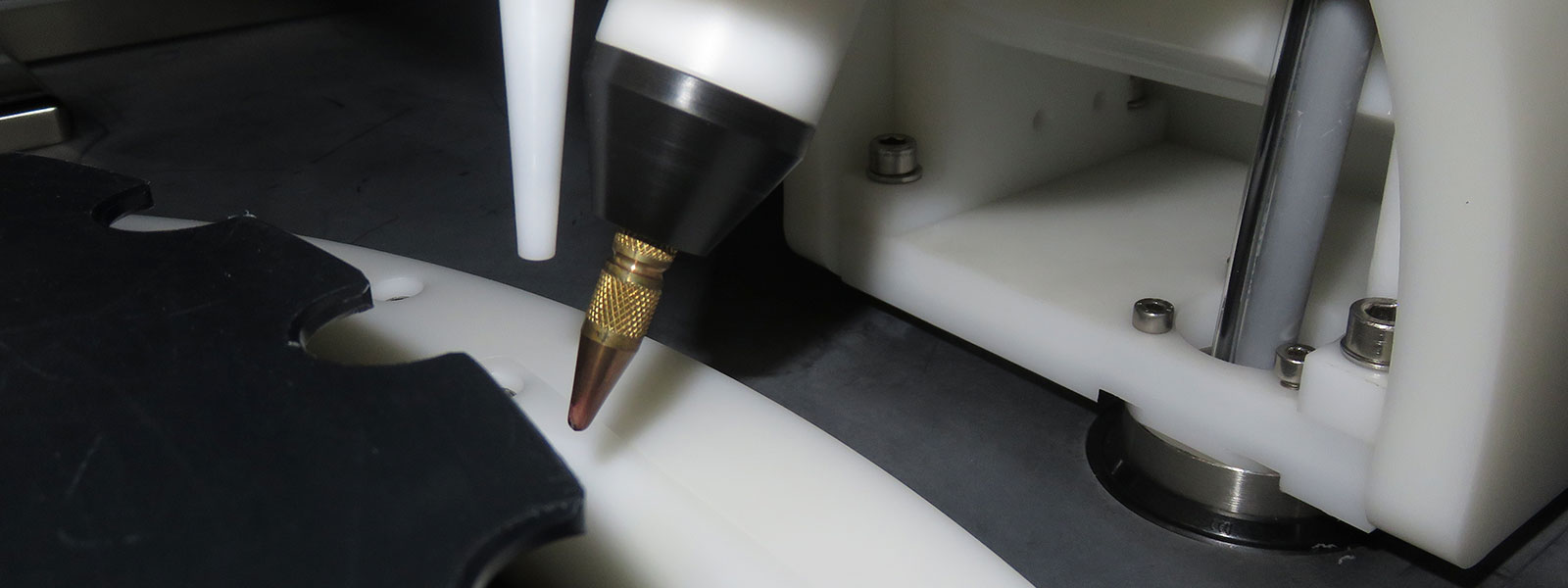

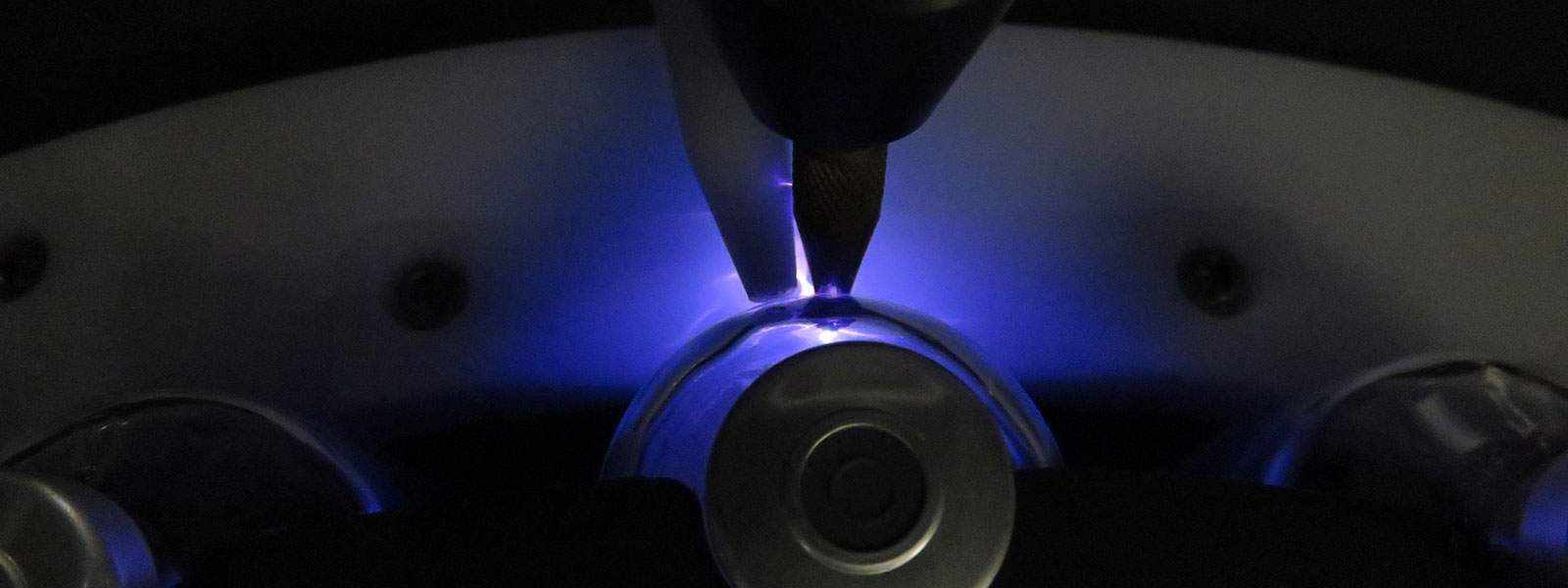

In 2005, Grifols patented an innovative procedure which used artificial vision technology to automate an important quality and control process: measuring the vacuum inside vials. The vacuum-sealed vials are fed into a monitoring station, where an electric current is applied to them. This forms an electric arc, which bridges the space inside the vial. An image of the arc is captured using a charge-coupled device (CCD) camera, which measures the luminous intensity of the arc against an adjustable threshold. If the intensity is below the threshold, the vial is rejected and separated from the other vials that have exceeded the threshold.

Automating a manual system

The first prototype was designed by the applied engineering team at Grifols Engineering, and was based on what was referred to informally as the “sparkometer” system. This was a manual system consisting of a handle, connected to a generator, which emitted the current required to generate a voltaic arc. If the vial contained a vacuum it lit up like a lightbulb.

The innovation rested not on the procedure of using vacuum detection as a quality control technique – something that was already performed manually – but rather on the automation of this process through the use of artificial vision. This was the first time such an approach had been applied in the sector.

“An image of the arc is captured using a charge-coupled device (CCD) camera, which measures the luminous intensity of the arc against an adjustable threshold. If the intensity is below the threshold, the vial is rejected and separated from the other vials that have exceeded the threshold.”

Bibliography

López Alvárez, D. (2005). Procedimiento y aparato para evaluar el grado de vacío en cuerpos cerrados de paredes transparentes. (Oficina Española de Patentes y Marcas Patente Nº ES20050002702). Link.