The KIRO® robot-calibration needle

Using laser sensor to ensure pinpoint accuracy

Technical file

Type of innovation: System

Scope: Hospital Pharmacy

Innovation leader: Shared leadership

Year: 2015

Period: From 2003

Geographical scope: International

Economic impact: High

Level of innovation: Evolutionary

Patent: Yes

Interdisciplinary connections: -

A major source of innovation for Grifols has been through partnerships with its portfolio companies. An example of this is the KIRO® needle calibration, designed for the KIRO® Oncology robot that had been developed by KIRO® Robotics, a company acquired by Grifols. KIRO® Robotics is a technology company that specializes in developing machinery and equipment to automate hospital processes. In particular, it has developed some of the world's most sophisticated hospital pharmacy technology: the KIRO® Oncology robot, which automates the preparation of intravenous medication for chemotherapy treatment, minimizing the risk for health professionals who are in contact with these highly toxic products. Some of the leading hospitals in the United States and the EU have adopted the KIRO® Oncology system, including Ann & Robert H. Lurie Children's Hospital of Chicago and the Smilow Cancer Hospital at Yale New Haven in the US, the Clínic Hospital and Vall d'Hebron Hospital in Barcelona, Hotel Dieu in Paris, and Finland's Helsinki University Hospital.

“The new system prevented puncture errors and thus improved the safety and efficacy of the preparation of intravenous medicines for chemotherapy patients, both for patients and for the health professionals who are in contact with these highly toxic products.”

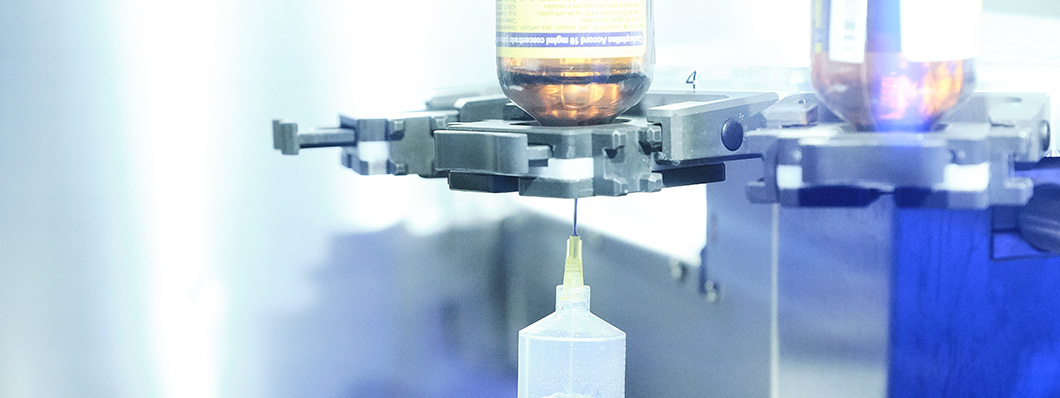

Preparing intravenous mixtures for chemotherapy

The KIRO® Oncology equipment automates the preparation of intravenous mixtures for chemoterapy. A robot manipulates a syringe which extracts a dose of medication from a vial, and then pierces the stopper and injects the medication into the final container, which may be a ready-to-use vial or one that has been reconstituted by the robot with saline, glucose or water solution. Commercially available syringes and needles are used, and these are changed after each preparation to prevent cross contamination.

Bringing engineering know-how to bear on a problem

Since the 1990s, Grifols has accumulated experience in designing closed filling systems, such as the Gri-Fill® system, for hospital pharmacies to produce sterile injectable solutions adapted to the requirements of individual patients. The Grifols engineering team realized that the commercially available, disposable needles used by KIRO® Oncology were not completely straight or perfectly centered, and this sometimes caused problems when piercing the stopper to inject the drugs into the bag. The team developed a solution to this problem using laser sensors, a technique that had already been applied to other manufacturing processes.

This involved using a micrometric sensor to monitor the actual position of the needle and compare it with the theoretical position on two different planes to calculate the orientation of the needle and the position of its tip. This information was then used to generate a new coordinate for piercing and angle of entry for each needle. The new system prevented puncture errors and thus improved the safety and efficacy of the preparation of intravenous medicines for chemotherapy patients, both for patients and for the health professionals who are in contact with these highly toxic products.

Bibliography

Rubio Aguilera, J. y Casanova Montpeyo, O. (2015). Método de corrección de la posición y desviación de una aguja de una jeringa en una máquina para la preparación automática de medicación intravenosa. (Oficina Española de Patentes y Marcas Patente Nº 201531768). Link

Grifols, S.A. (2014, September 19). Grifols acquires 50% of the share capital of KIRO Robotics for 21 million euros. [Press release]. Link

Related innovations

INSTRUMENT

The Gri-Fill® filling system